TinSil 80 Series Silicone Rubber

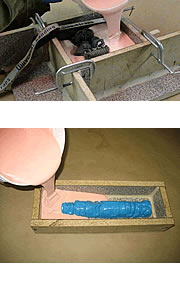

The TinSil 80-Series is a new series of tin-cured silicone mold rubbers from Polytek that are designed to offer reduced shrinkage upon cure and during casting, longer storage/library life once cured and longer useable mold life.

TinSil 80-15 is a 1A:10B mix ratio tin silicone with a soft, A~15 hardness and a tough, snappy, high-tear cure. The highest performance materials and processes have been used to develop this next-generation tin silicone for the most demanding casting applications. As with other Polytek silicone mold rubbers, TinSil 80-15 can be used to cast all media without release agents. TinSil 80-15 can be poured as supplied or thickened with TinThix liquid additive.

TinSil 80-30 is a 1A:10B mix ratio tin silicone with a mid-range, A~30 hardness and a tough, snappy, high-tear cure. The highest performance materials and processes have been used to develop this next-generation tin silicone for the most demanding casting applications. As with other Polytek silicone mold rubbers, TinSil 80-30 can be used to cast all media without release agents.

TinSil 80-15 is a 1A:10B mix ratio tin silicone with a soft, A~15 hardness and a tough, snappy, high-tear cure. The highest performance materials and processes have been used to develop this next-generation tin silicone for the most demanding casting applications. As with other Polytek silicone mold rubbers, TinSil 80-15 can be used to cast all media without release agents. TinSil 80-15 can be poured as supplied or thickened with TinThix liquid additive.

TinSil 80-30 is a 1A:10B mix ratio tin silicone with a mid-range, A~30 hardness and a tough, snappy, high-tear cure. The highest performance materials and processes have been used to develop this next-generation tin silicone for the most demanding casting applications. As with other Polytek silicone mold rubbers, TinSil 80-30 can be used to cast all media without release agents.

| 80-15 | |||

| Mix Ratio: 1A to 10B by weight | Specific Volume: 25.3 in³/lb | Viscosity: 12,000 cP | Color: Peach |

| Demold Time: 24 hours @ 77°F | Shore A Hardness: 15 | Pour Time: 30 min | |

| 80-30 | |||

| Mix Ratio: 1A to 10B by weight | Specific Volume: 23.7 in³ / lb | Viscosity: 17,000 cP | Color: Peach |

| Demold 77°F 24 hrs | Shore A Hardness: 30 | Pour Time: 45 min | |

TinThix - TinSil Thickener

Transform your TinSil silicone liquid rubbers into brushable systems with our Tinsil thickeners. Designed for easy mixing, this liquid thickener creates a creamy, brushable consistency. Customize the level for a light gel or thicker silicone rubber paste. Achieve the perfect face coat consistency with just a few drops.