Metal Coatings

The Metal Coatings are ground metal suspended in a non-toxic water based acrylic binder. They may be applied to both metal and non-metal surfaces such as glass, wood, ceramics, concrete, foam, and resin.

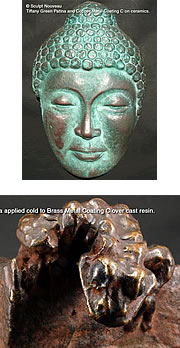

All of the Dye-Oxide Patinas, Universal Patinas, Vista Patinas, Solvent Dyes, Patina Stains, and Finishing Waxes work well with the Metal Coatings allowing endless possibilities for finishes. Among the Traditional Patinas, Liver of Sulfur (brown) and Tiffany (green) patinas work the best with the Metal Coatings.

The Metal Coatings are very durable outside (10 to 15 years) and are non-hazardous. One Gallon of Metal Coating will cover 100 square feet (this includes the recommended two layers).

The Metal Coatings are available in two different formulas - B and C. Patinas may be applied to both whether wet or dry. Once dry, either may be burnished with steel wool in order to highlight or adjust the patina. Additionally, more patina may be added after burnishing. Type C contains more metal than Type B and dries hard enough to be polished with a polishing wheel. Type C comes bundled with a catalyst and hardener.

When applying the Metal Coatings to ferrous metals (iron, steel, and aluminum), a primer must be used to protect the underlying metal.

Metal Coatings B and C are available in Copper, Bronze, Brass, and Silver.

Metal Coating

All of the Dye-Oxide Patinas, Universal Patinas, Vista Patinas, Solvent Dyes, Patina Stains, and Finishing Waxes work well with the Metal Coatings allowing endless possibilities for finishes. Among the Traditional Patinas, Liver of Sulfur (brown) and Tiffany (green) patinas work the best with the Metal Coatings.

The Metal Coatings are very durable outside (10 to 15 years) and are non-hazardous. One Gallon of Metal Coating will cover 100 square feet (this includes the recommended two layers).

The Metal Coatings are available in two different formulas - B and C. Patinas may be applied to both whether wet or dry. Once dry, either may be burnished with steel wool in order to highlight or adjust the patina. Additionally, more patina may be added after burnishing. Type C contains more metal than Type B and dries hard enough to be polished with a polishing wheel. Type C comes bundled with a catalyst and hardener.

When applying the Metal Coatings to ferrous metals (iron, steel, and aluminum), a primer must be used to protect the underlying metal.

Metal Coatings B and C are available in Copper, Bronze, Brass, and Silver.

Metal Coating

Metal Powders - Copper, Bronze, Brass, Aluminum

Metal powder can be added to Forton MG or polyurethane casting resins to produce a cold cast piece with a metal surface. Various patinas can then be applied to the metal surface to achieve any desired look.

Prime-It

When applying traditional or acid patinas to the Metal Coatings over iron, steel, or aluminum, a primer must first be used to protect the underlying metal from corrosion. This one part primer is recommended to protect the original ferrous surface. This is the quickest curing and strongest primer available for ferrous metals. This is also a great product to use over polyurethane products before applying the Metal Coatings.

Practical coverage: 200-350 square feet.

This amazing one part, water base, no VOC primer was designed for use in severe industrial environments for the protection of steel structures. It provides excellent chemical, abrasion, and corrosion resistance.

Any surface should be cleaned before applying the primer. Spray or brush on.

Practical coverage: 200-350 square feet.

This amazing one part, water base, no VOC primer was designed for use in severe industrial environments for the protection of steel structures. It provides excellent chemical, abrasion, and corrosion resistance.

Any surface should be cleaned before applying the primer. Spray or brush on.